PAR

FOR TRADE FZE LLC

IMPORT & EXPORT SERVICES

GENERAL TRADING

Beirut,Lebanon

00961 3 640 766

Dubai, UAE

00971 569093678

PIPES, PUMPS AND VALVES

S Series

Screw Pumps

Blackmer’s S Series Screw Pumps are self-priming double ended positive displacement pumps that are offered with or without external timing gears and bearings. Our twin and triple screw designs provide complete axial balancing of the rotating screws and with our timing technologies eliminate metal-to-metal contact within the pump. Blackmer’s carefully crafted screw technology rotates within a cylindrical cavity, transferring fluid and materials along the screw's spindle.

SMVP

Sliding Vane Pumps

Blackmer has combined our proven sliding vane design with a seal-less magnetic coupling to meet the growing need for zero shaft leakage when handling expensive, hazardous or hard to seal fluids. Environmental concerns, workplace safety, EPA requirements, and local government agency regulations may may the "Best Available Control Technology" (BACT) for certain chemicals.

1/4" TC-X030 Series Pump

The TC-X030 Series compact pumps offer minimal flow rates and feature the new Looped C™ Air Motor Technology (patent pending).

3/8" TC-X100/101 Series

AODD Pumps

TC-X100/101 pumps are specially designed for extremely low speed fluid transfer, frequent start/stop and dead head type applications with a choice of multi-port options.

Etaline R Pump

Vertical close-coupled, in-line circulator pump with volute casing and standardized motor. Applications include: hot water heating systems, cooling circuits, air-conditioning, water and service water supply systems, industrial recirculation systems.

EnviroGear® Internal Gear Pumps

Maag Industrial Pumps, part of Pump Solutions Group (PSG)

EnviroGear®, part of Dover Corporation’s PSG®, is proud to offer this innovative, durable and environmentally friendly positive displacement gear pump. EnviroGear Internal Gear Pumps save you money by providing a low initial cost, high performance, and low maintenance costs. Our revolutionary seal-less design with patented between-the-bearing support system effectively eliminates leaks and mechanical wear, helping to increase personnel and environmental safety.

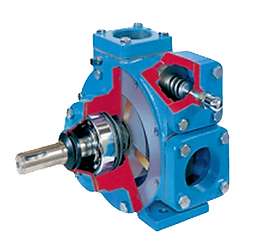

G Series Internal Gear Pumps

Maag Industrial Pumps, part of Pump Solutions Group (PSG)

G Series Internal Gear Pumps are reliable, durable, and cost effective. They are well suited to industrial applications involving both thin and viscous liquids. These cast iron G Series internal gear pumps are offered in a variety of connection sizes and flow rates. They are also designed to drop directly into competitive (Viking®, Gorman-Rupp® and Tuthill®) installations. These pumps have the same inlet/discharge connections, footprint, and drive shaft size/positioning as competitor models. The G Series pump performance is also equivalent to competitors, simplifying the upgrade process.

Abaque Peristaltic Hose Pump

With more than 20 years of experience pumping and transferring difficult chemicals and fluids, the Abaque Peristaltic Hose pump will handle your toughest pumping needs – from abrasive and aggressive to shear-sensitive and viscous fluids. Abaque pumps currently operate in some of the most demanding environments including mining, water and wastewater treatment, energy, chemical processing and OEM applications.

Your solutions for abrasive products containing suspended particles (Up to 77 m3/h) 16 bars pressure (232 psi).

Micro C Series

Eccentric disc pumps

Your solutions for continuous transfer and low-flow metering (800 liters/h) at 3 bars and 15 bars pressure.

HXL Series Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use HXL Series ductile iron pumps for high volume transfer of non-corrosive liquids from thin solvents to heavy oils and molasses.

A Series

Eccentric Disc Pumps

Your solution for a wide variety of products (Up to 50m3/h).

C Series

Eccentric Disc Pumps

Your solutions for Air sensitive and shear sensitive products (Up to 36m3/h) maximum pressure 9 bars.

CC8 TanktruckVane Pumps

Your solution for Petroleum product transfer on tanker (Up to 80 m3/h) 8 bars.

P SeriesVane Pumps

Your solution for highly viscous products (Up to 110 m3/h) 12 bars.

SLC & SLS Series

Eccentric Disc Pumps

Mouvex SLC Eccentric Disc Pumps have been designed to provide premium performance and the ultimate in full containment and safety in chemical-processing applications. They feature a unique seal-less design with a double stainless-steel bellows that ensures durability, safety and product containment. The result is a pump that delivers very high suction and discharge pressures that allow it to self-prime and fully maximize product containment. Ideal for safe transfer of critical high-value fluids.

S Series

Eccentric Disc Pumps

Your solutions for products that have to meet rigorous sanitary standards (Up to 12m3/h) 6 bars and 10 bars pressure.

CRL Series Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use CRL Series ductile iron pumps for liquid CO2 transfer applications.

GX Series Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use the GX Series cast iron pumps with integral gear reducers for clean, non-corrosive industrial liquids and petroleum products.

TX Series

Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use TX Series cast iron transport pumps for clean, lubricating liquid petroleum products, biofuels or solvents.

TXV Series

Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use TXV cast iron transport pumps for high temperature and high viscosity applications.

LG1 Series Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use the LG1 Series ductile iron, UL-listed pumps for LPG or NH3 transfer applications.

ML Series Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use ML Series ductile iron pumps for everything from thin, non-lubricating solvents to highly viscous liquids or abrasive slurries.

RC 20/25 Regenerative Turbine Pumps

Blackmer offers Ebsray Series regenerative turbine pumps to the Americas market for LPG and Autogas applications.

Recognized as a global leader in Autogas-handling applications – with decades of reliable performance in thousands of installations worldwide – Ebsray products are known for efficiency, reliability, and performance.

Ebsray Series regenerative turbine pumps have been specifically designed and precision-built for high-pressure transfer in Autogas applications. The secret to the success of these pumps is the innovative impeller design, which optimizes hydraulic performance resulting in high differential pressures even at low flow rates, a critical consideration for Autogas applications. Ebsray pumps also feature a smooth, quiet operation and long pump life.

SGL Series

Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use SGL Series ductile iron pumps for liquefied gas transfer applications.

STX Series Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use STX Series stainless Steel transport pumps for high temperature and high viscosity applications.

X Series

Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

Use X Series cast iron pumps for clean, non-corrosive industrial liquids and petroleum products.

S Series (Triple)

Screw Pumps

Maag S Series Triple Screw Pumps are positive displacement rotatory pumps which adopt a cycloid profile of meshing principals at the screw profile. The power spindle is driven by a motor and the idler spindles are driven by fluid hydraulic power in an intermeshing screw groove. Hydraulic force on the spindle is balanced by the hydraulic load on the balanced piston. These pumps are ideal for handling smooth constant flow across a wide range of viscosities, temperatures and pressures without solid content. Three models are available.

System One Centrifugal Pumps

The simplest type of centrifugal pump is the single stage machine that consists fundamentally of a rotating element, called an impeller, and a casing. Liquid is led to the eye or center of the impeller and is set into rotation by the impeller vanes. By virtue of centrifugal force the liquid is thrown from the rim or periphery of the impeller with a considerable velocity and pressure. The casing, which closely surrounds the impeller, has a volute shaped passage of increasing area, which collects the liquid leaving the impeller, and converts a portion of its velocity energy into additional pressure energy. This casing passage leads to the discharge nozzle of the pump where it is forced into the discharge piping.

S Series (Twin)

Twin Screw Pumps

Maag’s S Series Twin Screw Pumps (WTG) are double-suction, self-priming twin screw pumps with external bearings and timing gears transmission. They are especially suitable for the delivery of fluids free of solid substances and/or with little abrasiveness.

Maag S Series Twin Screw Pumps with non-timing (NTG) gear transmission feature a single-suction design. The axial pressure on the hydraulic components is compensated by a balance piston. Metal contact exists between the screw profiles and casing bore. The S Series (NTG) Twin Screw Pumps transfer lubricating fluids with higher viscosities, such as bitumen and residual oil, at medium or high temperatures.

Multi-phase Pumps are commonly used in oil fields with untreated streams. In order to satisfy the demands of oil, gas and water containing small particulates, the Multi-phase Pumps adopt a unique screw profile and design, along with a special pump casing chamber, to achieve an increase in mixture and heat distribution. A variety of materials and seals are available to meet challenging operating conditions in the field.

B-Pumps Deep Well Turbine Pumps

Main pump parts are the Pump Bowl Assembly, Column Pipe Assembly, and Discharge head assembly. Bowl assembly consists of single or multistage radially split, interchangeable intermediate bowls. Column Pipe Assembly consists of interchangeable lengths of the column pipes and variable setting depth. Discharge head assembly consists of discharge head with packed stuffing zone/mechanical seal and thrust bearing arrangement (in case of solid shaft drive only).

PMM Permanent Magnet Motor

The Borets Permanent Magnet Motor (PMM) is designed for the same ESP systems as induction motors, and also for PCPs. However, the PMM shows better performance in harsh environments, such as viscous fluids, high solids content, unstable inflow, low production, post hydro-fracturing or any other artificial lift methods applied.

SRD991 Top Mount, Valve Positioner

The top-mounted SRD991 digital positioner is integral with the Type 766 actuator, spring opposed diaphragm actuator designed specifically to fit the Research Control Valve body-bonnet assembly. The unique positioner is compatible for both the 1/4 in. and 1/2 in. actuator. The unit functions as an air-to-open actuator retracting the stem and opening the valve on an increasing instrument signal. This solution should be used when the application calls for high positioning accuracy or when greater force is required over the standard actuator such as in the case of high shutoff pressures or excess packing friction. This linear connection creates a quicker and more accurate control element. The SRD991 top-mount positioner is available with a large amount of benefits including a LCD screen, protocols and diagnostics. All the diagnostics features can be easily configured and displayed by the Positioner DTM. Moreover, the Positioner DTM enables a complete health report of the valve with all data of configuration and diagnostics. The simple installation and setup of the SRD991 positioner allows an easy upgrade to any BLRA pneumatic positioner.

ProVane Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

The ProVane Ductile iron or Stainless Steel motor-speed pumps are used for process applications where efficiency, performance and value are desired.